Comprehensive Evaluation on Typical Concerns and Solutions in Lift Fixing

In the realm of lift repair service, a careful evaluation of usual concerns and their corresponding services is extremely important to guaranteeing the smooth procedure and safety and security of these important vertical transportation systems. From the vexing troubles with lift doors to the intricate intricacies of electrical malfunctions, a myriad of difficulties can afflict lift capability (lift service company). As we explore the intricacies of elevator maintenance, a comprehensive understanding of these concerns and the efficient strategies for settling them becomes an essential facet of guaranteeing optimal lift efficiency

Elevator Door Issues

Among the most common obstacles come across in lift upkeep is dealing with lift door malfunctions. The smooth operation of elevator doors is essential for guest safety and efficiency. A malfunctioning door can cause hold-ups, aggravation, and also possible dangers.

Lift door problems can come from numerous factors, such as defective door sensors, misaligned doors, damaged rollers, or problems with the door driver device. These malfunctions can result in doors closed or shutting properly, getting stuck midway, or also shutting too rapidly, positioning a threat to guests entering or exiting the lift.

To deal with lift door breakdowns successfully, maintenance professionals should conduct regular assessments, lube moving parts, change door timings, and replace damaged elements without delay. Furthermore, executing preventive upkeep routines can help recognize and solve potential door concerns prior to they rise. By focusing on lift door upkeep and immediately addressing breakdowns, structure owners can guarantee the risk-free and effective operation of their lifts.

Electrical Breakdowns

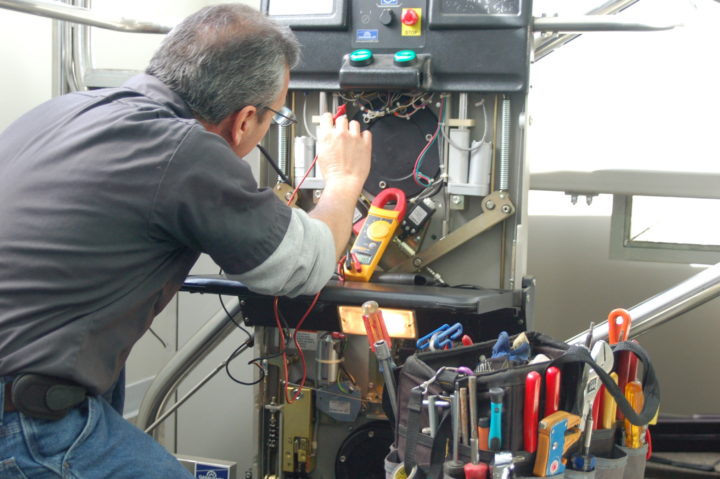

Resolving electrical breakdowns in lifts needs comprehensive analysis analyses and exact troubleshooting methods to guarantee the safe and trustworthy performance of the elevator system. Electrical malfunctions can materialize in different ways within a lift system, varying from problems with the control panel, damaged wiring, power supply issues, to troubles with sensing units and interlocks. When coming across electrical breakdowns, it is crucial for maintenance personnel to adhere to a methodical technique. This consists of examining the power supply to the lift, inspecting wiring for any indications of damages or wear, and checking the capability of key parts such as the control panel and emergency quit switch. Making use of diagnostic tools such as multimeters and circuit testers can aid in pinpointing the origin of the electrical malfunction properly. In addition, making certain that all electrical links are safe and up to code is necessary in preventing future breakdowns. By resolving electric problems quickly and successfully, lift service technicians can keep the safety and efficiency of great post to read elevator operations.

Hydraulic System Troubles

A malfunctioning pump can lead to the lift not being able to create sufficient hydraulic pressure to run efficiently. Regular assessment, maintenance, and prompt replacement of hydraulic components can stop these issues and ensure the smooth performance of the lift system.

Control System Problems

Control system malfunctions can interrupt the smooth operation of lift systems and position safety dangers if not quickly attended to. When the control system fails to communicate efficiently with the lift components, it can result in unpredictable motions, unforeseen stops, or full closures.

To address control system problems, lift repair service professionals have to perform detailed diagnostics to pinpoint the source of the issue. This may entail testing the electric links, adjusting sensors, or reprogramming the control software. Normal upkeep checks can help prevent these glitches by identifying potential issues before they intensify (lift servicing companies). By immediately attending to control find out system malfunctions, lift drivers can guarantee the safety and integrity of their systems for travelers and stop costly downtime.

Safety Features Concerns

In guaranteeing the optimum capability of lift systems, alertness towards the stability of security functions ends up being paramount following the recognition and resolution of control system problems. Safety and security functions in lifts are made to prevent injuries, malfunctions, and mishaps. Typical concerns connecting to safety and security attributes consist of issues with door sensors, emergency situation brakes, overload sensors, and fire-rated touchdown doors. Door sensing units are important for discovering obstructions and making sure doors do not shut on passengers. Emergency situation brakes are important for stopping the lift in case of a mechanical failure. When it exceeds its weight capacity, overload sensors aid protect against the lift from running. Fire-rated touchdown doors are essential for including fires and securing occupants throughout emergency situations. Normal maintenance, examinations, and testing of these safety and security attributes are important to ensure they are working properly. Dealing with safety function concerns without delay can substantially minimize the risk of mishaps and boost the total safety of lift procedures.

Conclusion

To conclude, common issues in lift fixing include lift door concerns, electrical breakdowns, hydraulic system problems, control system glitches, and safety and security functions problems. It is essential for maintenance teams to resolve these issues immediately to make certain the safe and effective procedure of lifts. By carrying out proper upkeep methods and routine examinations, these problems can be identified and dealt with efficiently to stop any interruptions in elevator feature.

In making sure the optimal performance of lift systems, caution in the direction of the honesty of security attributes ends up being critical complying with the recognition and resolution of control system problems - platform lift dimensions.In verdict, usual problems in lift repair include elevator door problems, electric breakdowns, i loved this hydraulic system problems, control system problems, and safety attributes problems